The elementary UV disinfection requirement in the treatment process is the chemical-free inactivation of viruses, bacteria and parasites such as Cryptosporidium and Giardia - without creating unwanted disinfection by-products.

Moreover, further aspects play an ever more important role for water utility operators: Sustainability, environmental compatibility and last but not least energy consumption are important factors for choosing the right technology in times of decreasing resources.

Compared to UV disinfection systems with medium-pressure lamps, the WEDECO K series with the highly efficient WEDECO

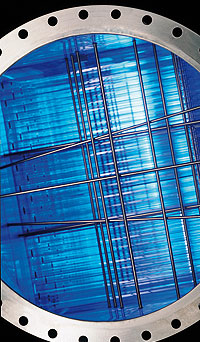

Spektrotherm lamp technology is the most beneficial solution for meeting ecological and economic requirements. The Spektrotherm® low-pressure high-intensity UV lamp sets benchmarks in terms of UV performance and economic efficiency. A special doping (amalgam/indium alloy) and electronic ballasts developed especially for this type of lamp lead to outstanding characteristics for the operation of the UV system.

The low operational lamp temperature results in little formation of deposits on the quartz sleeves. Therefore, cleaning is only required very rarely and there is no need for an expensive mechanical wiping mechanism.

Vario dose control: Never use more power than required

The Spektrotherm® lamps are powered by the latest electronic ballast technology and controlled by a highly selective calibrated UV intensity sensor. Based on the actual UV dose requirement, the lamp power setting is varied between 50 and 100%, resulting in the lowest power consumption possible

Energy-efficiency: The decisive advantage of the WEDECO K series

Compared to other UV products on the market, the WEDECO K series is usually the economic solution due to low energy and maintenance costs, long UV lamp life, flexible dose control and attractive investment costs.

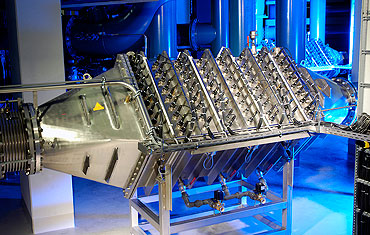

The WEDECO K Series is the solution for large flow drinking water applications. This UV reactor provides the capacity for treating large amounts of drinking water with UV light. The high performance and the low headloss is unmatched in the industry.

The WEDECO K Series is the solution for large flow drinking water applications. This UV reactor provides the capacity for treating large amounts of drinking water with UV light. The high performance and the low headloss is unmatched in the industry.